3D Printing Helping to Make a Final Part

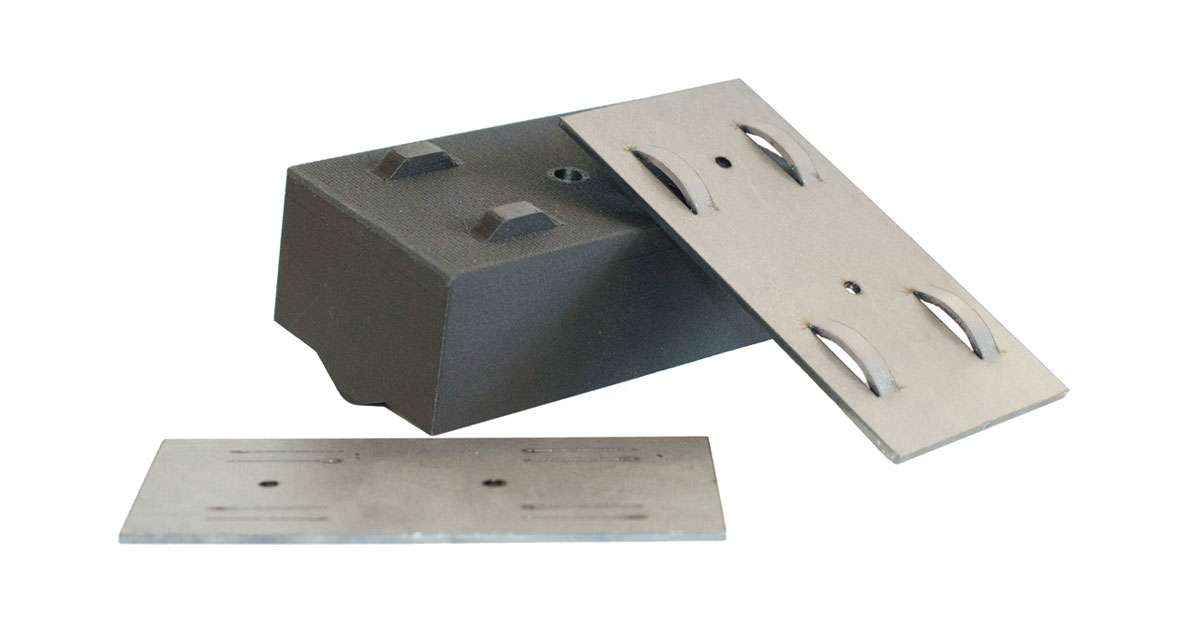

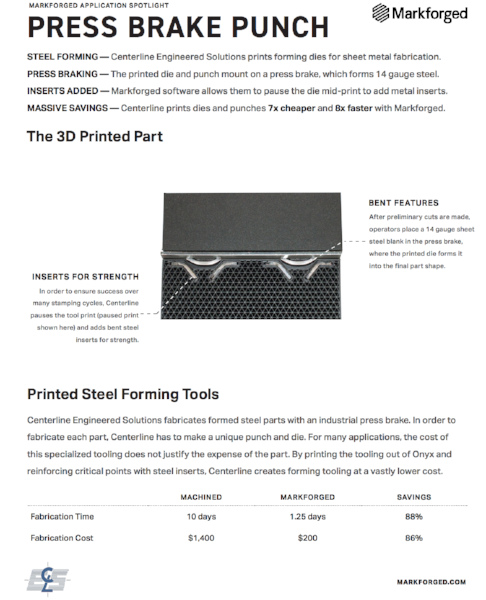

As an update to the previous 3D printed Press Brake part, we have now successfully produced an order for our customer using the 3D printed Die and Punch. Markforged, the manufacturer of the Mark II printer, decided to do a case study of this application which can be found on their website.

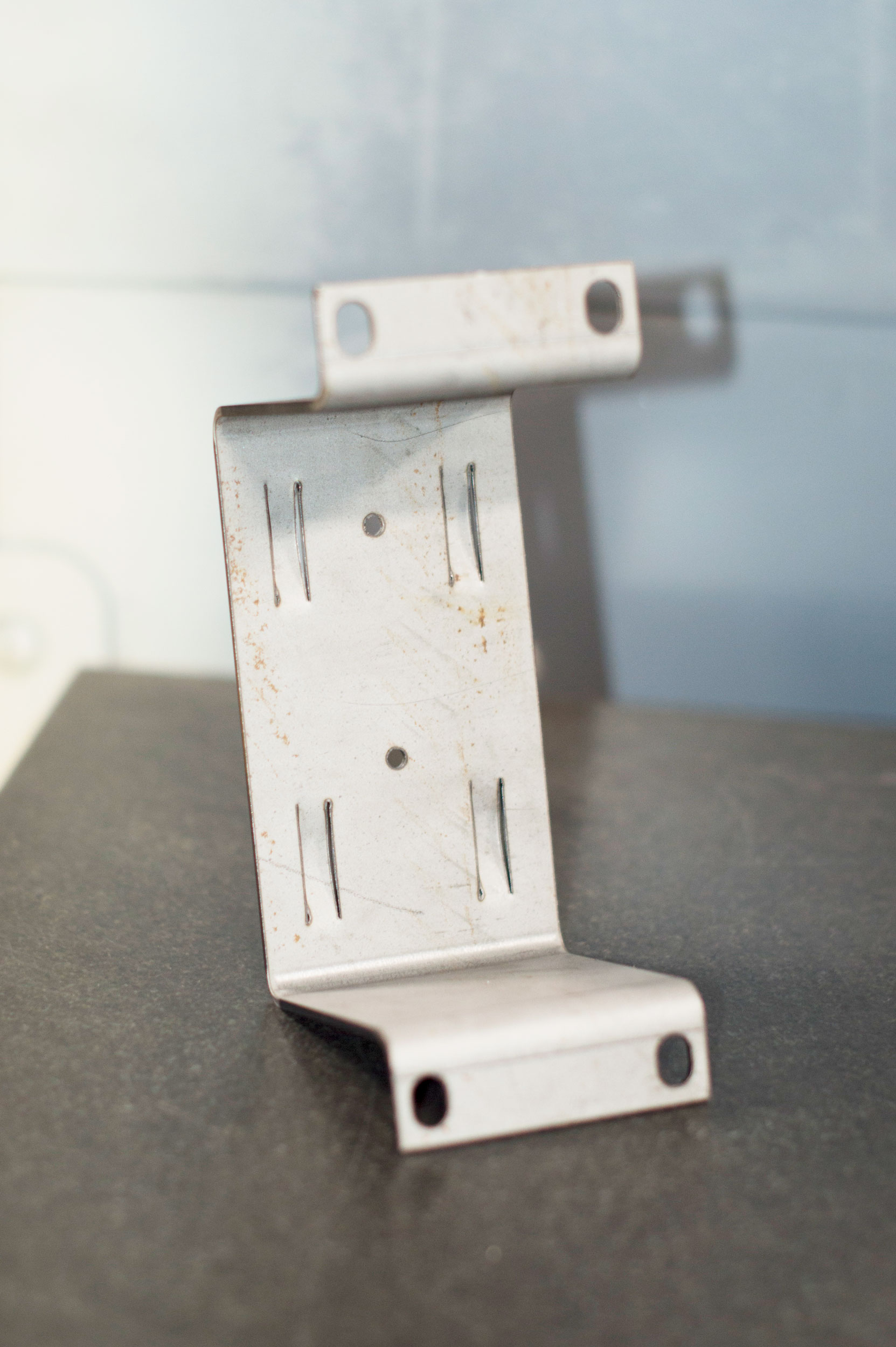

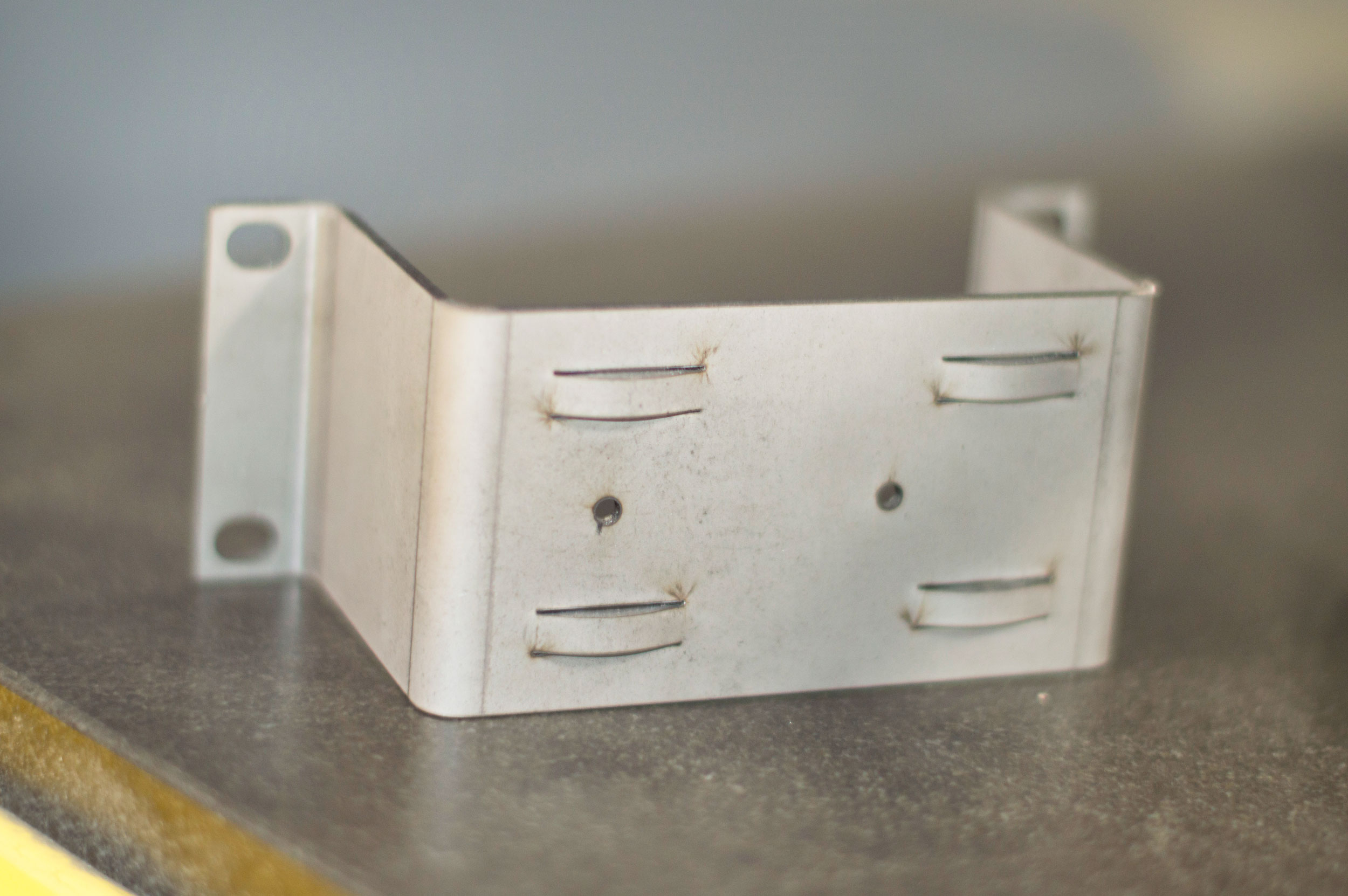

It should be clear that this application is an example of lancing and not bending of sheet metal.

The 3D printed materials were able to be printed in a cost efficient manner and decided for a very specific application.

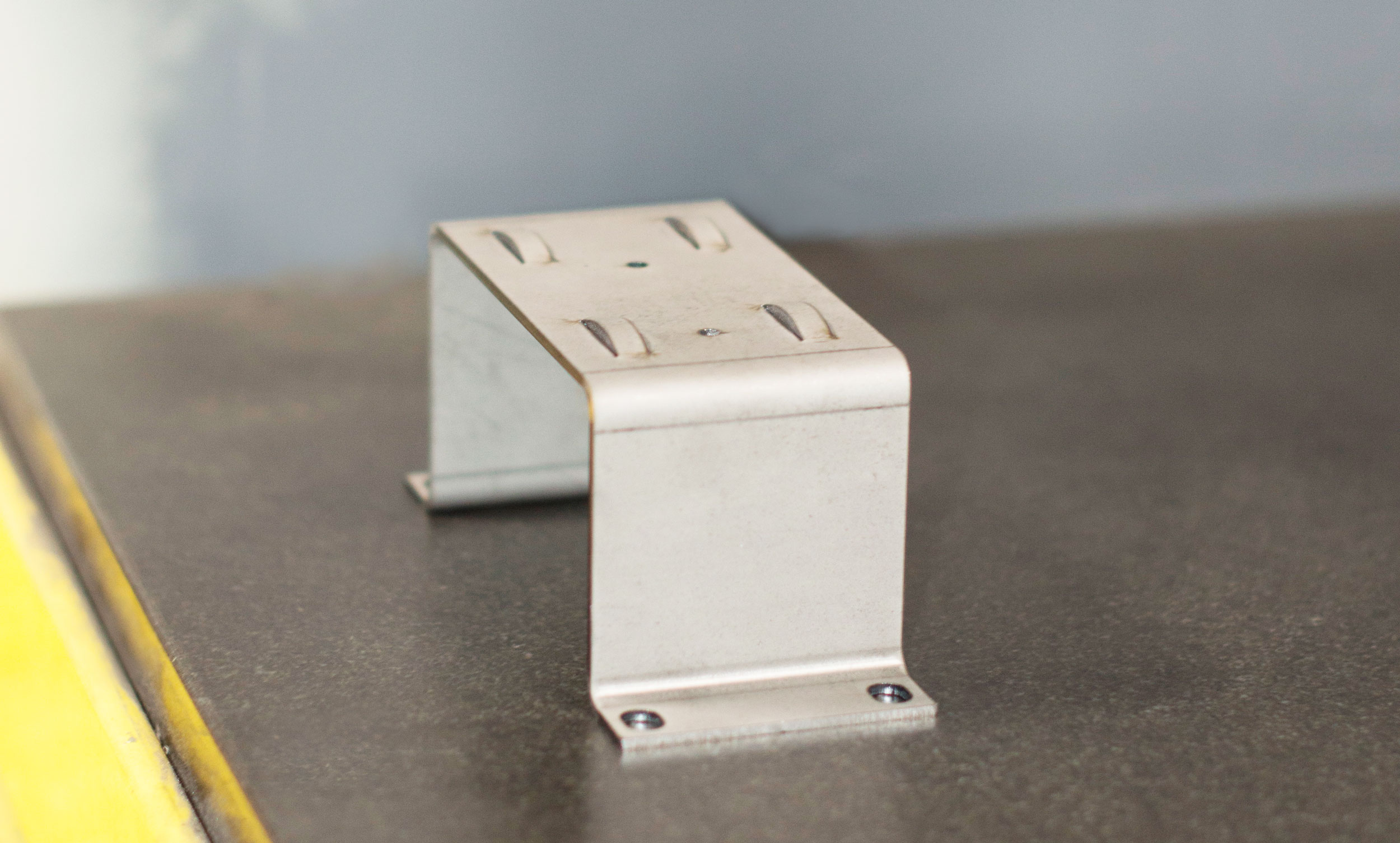

After a few adjustments to the press brake we were able to form the part with using a force of approximately 3 tons.

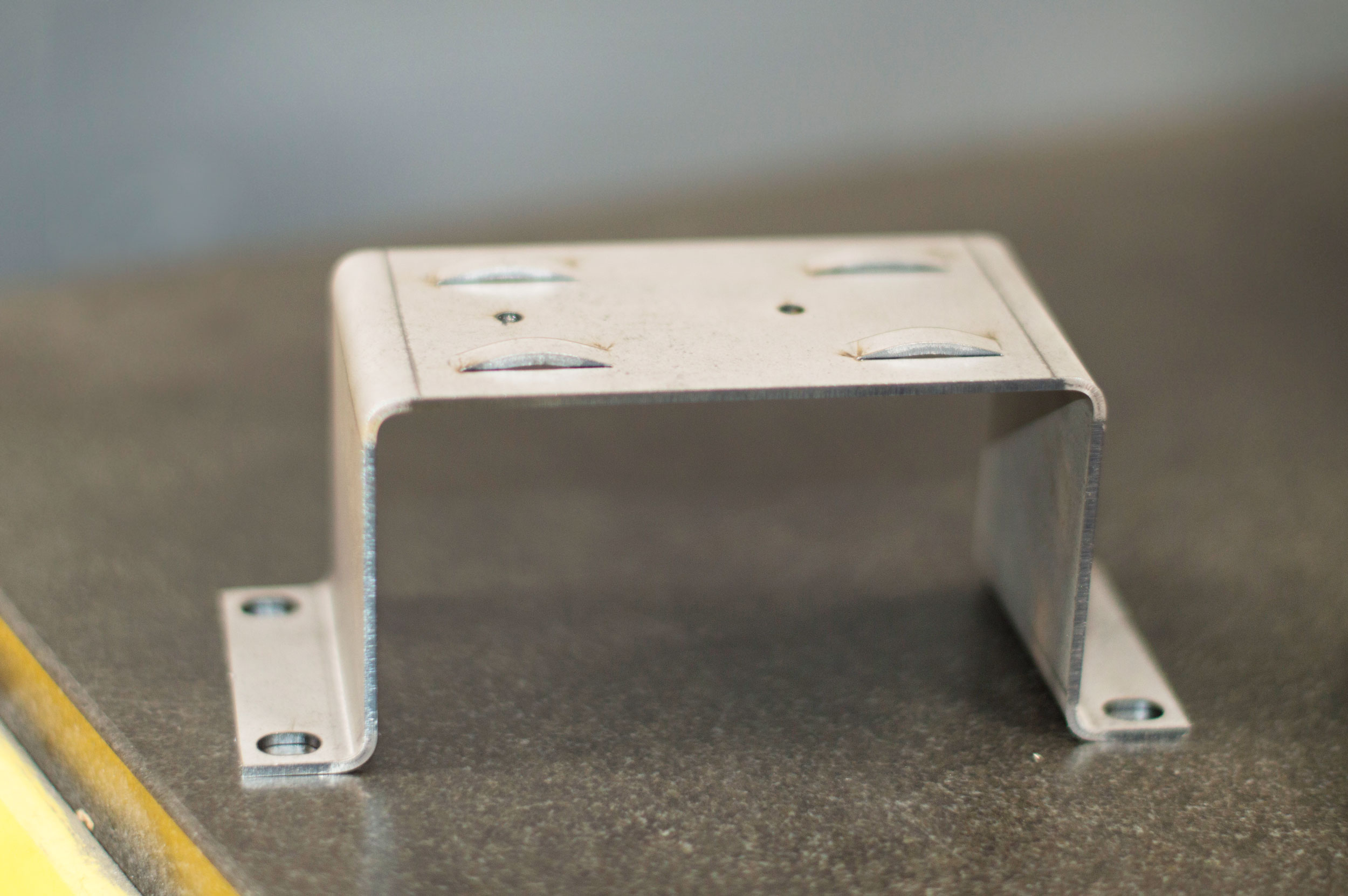

The final part contained the formed area and an assortment of 90 degree bends that were made with our typical press brake dies which are made of metal.

The outcome was a success for our customer which is the bottom line for any order. We learned a lot about designing and utilizing dies and punches with 3D printed material. It is our experience that 3D printed material can be utilized to assist with our operational efficiency and effectiveness.