CES Rotary Shear Model 80P

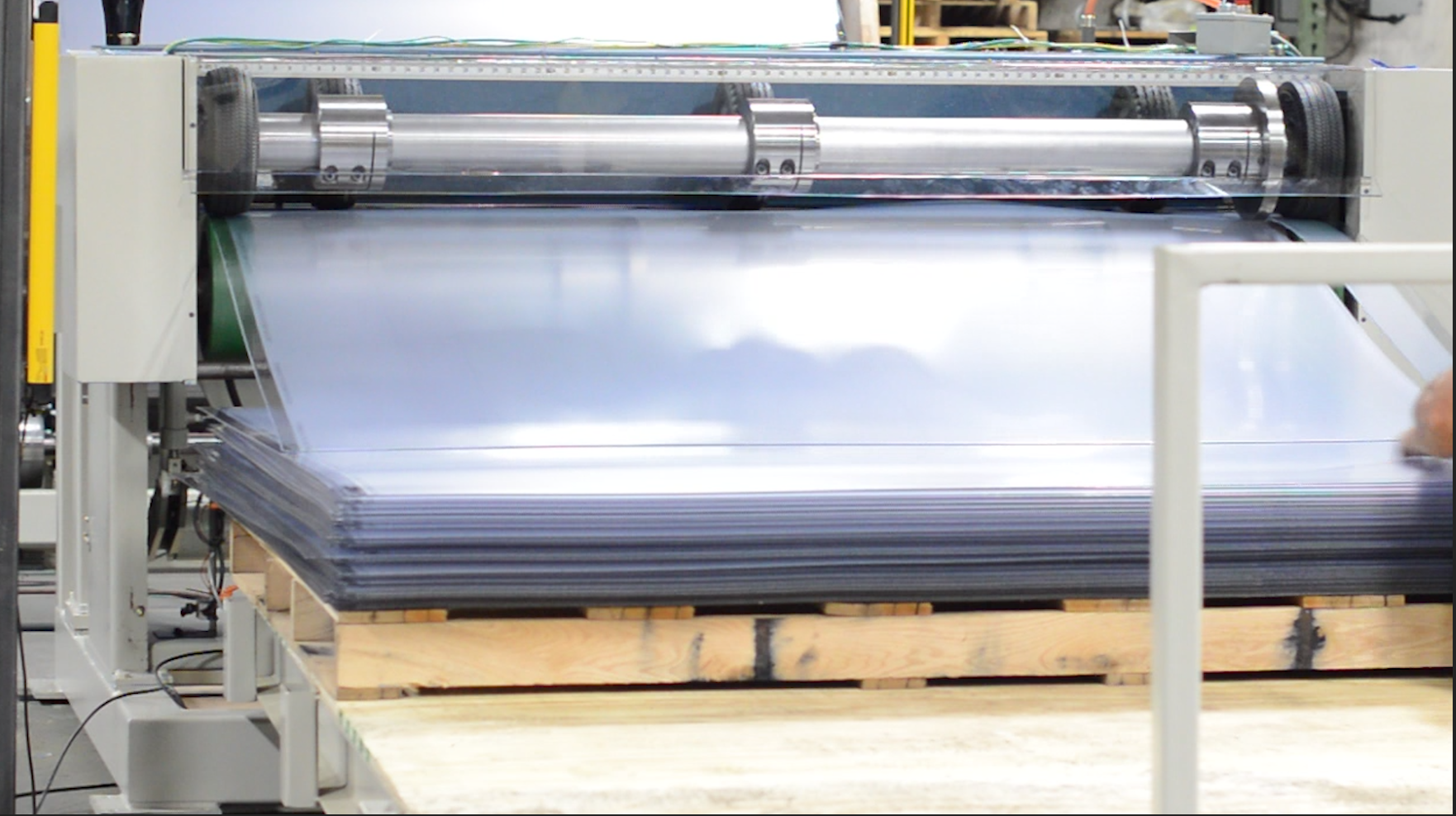

The Model 80P is a fully automated slitting machine. The Model 80P automatically removes material (polycarbonate, plastics, rubber, etc.) from a reel or coil with a maximum material width of 80 inches. The material is cut to length using a guillotine shear with a minimum cut length of 12” and a maximum cut length of over 20 feet. The material is immediately slit into sections (maximum of 4 sections) with dimensional tolerances within +/- 1/8”. The Model 80P operates at a speed of up to 40 feet per minute. The Model 80P has the capability to significantly improve productivity by reducing manual material handling.

speed and precision

The Model 80P machine speed is configurable with a maximum of 40 feet/minute. The Model 80P can be configured to cut and slit material of various thickness. This configuration will depend upon the type of material.

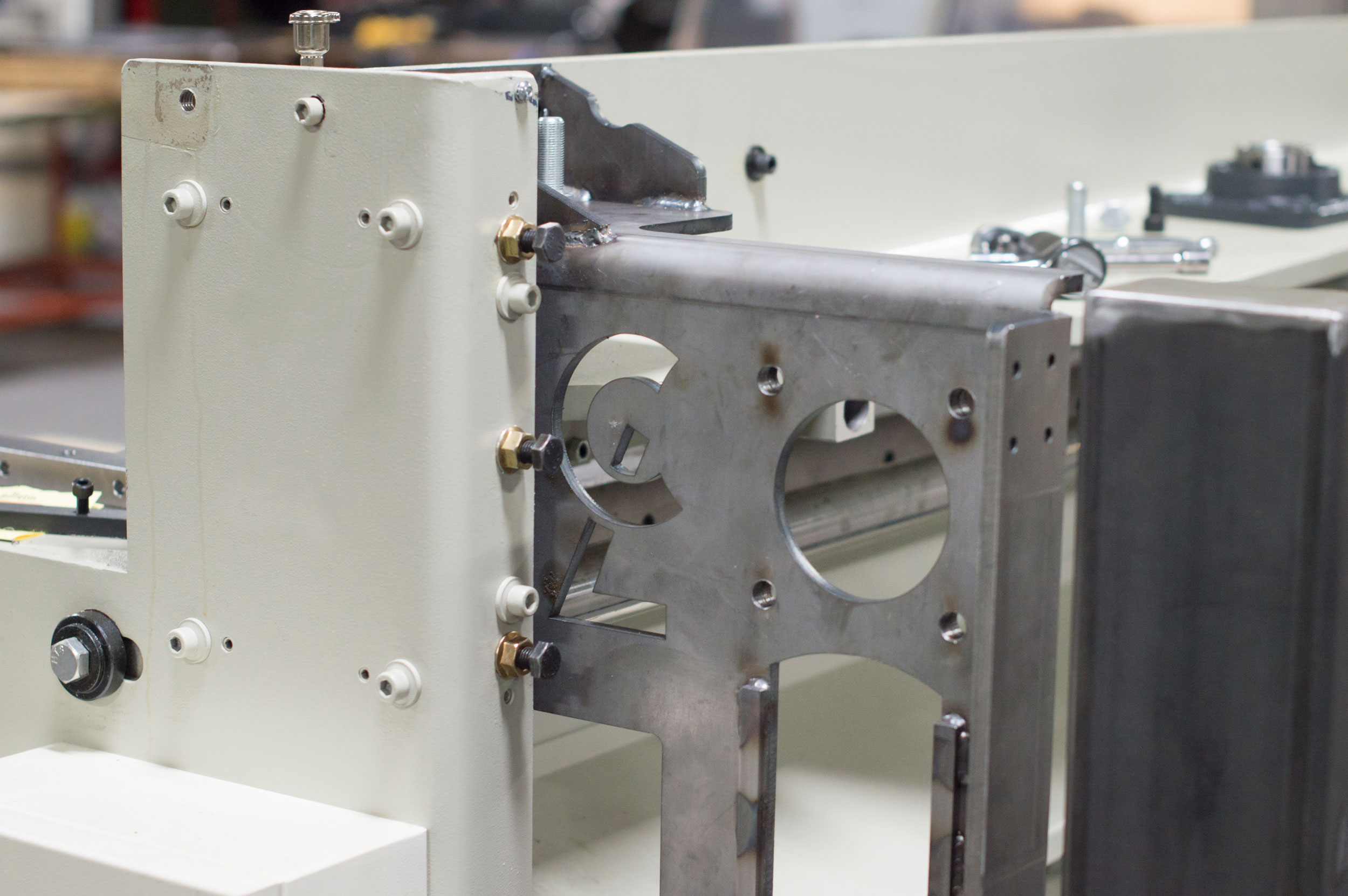

Designed and Engineered for reliability and repeatability

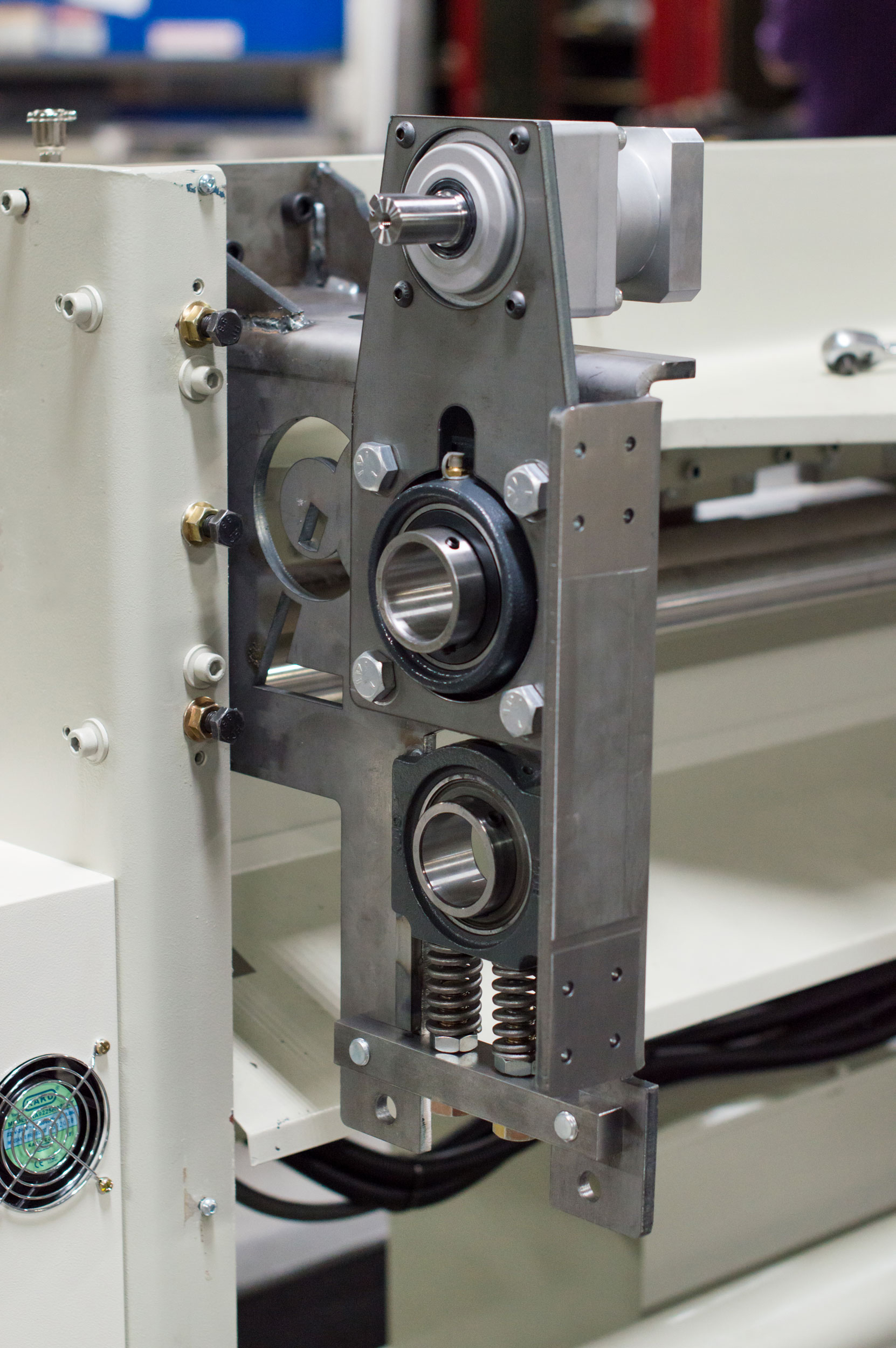

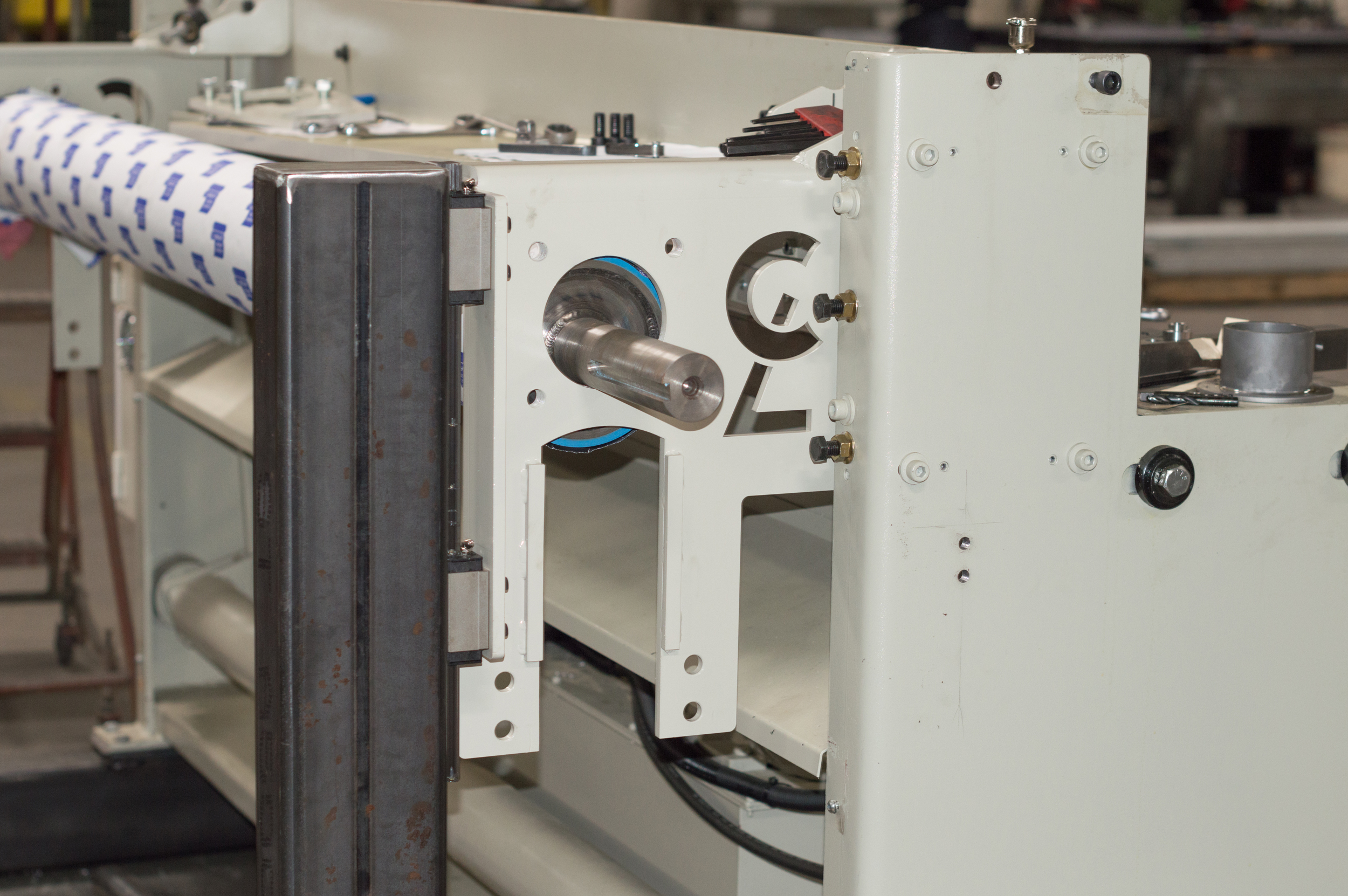

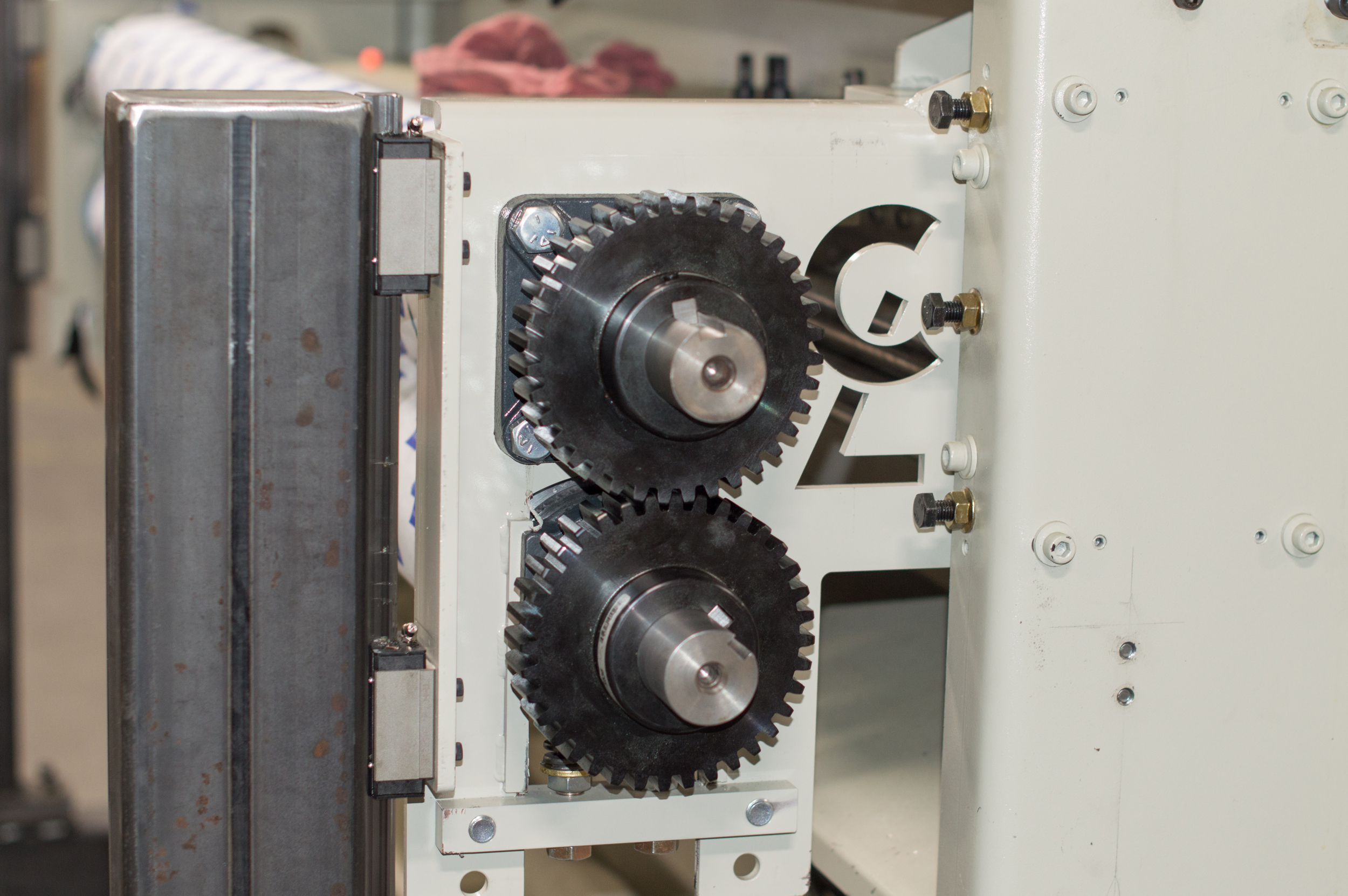

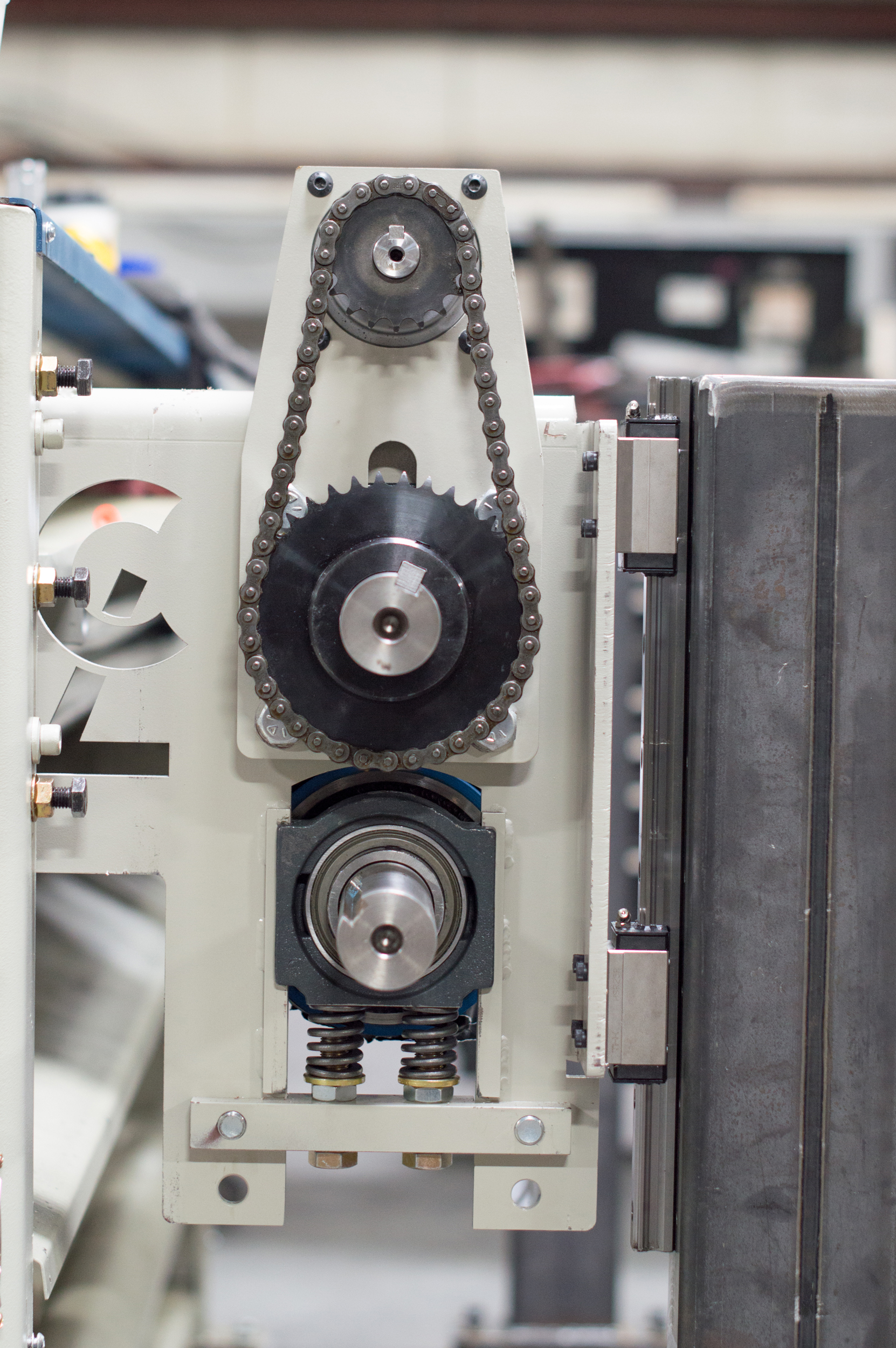

The Model 80P was designed specifically for industrial use. Each component was engineered to maximize the durability of the machine and provide quality slitting and cutting. The Model 80P takes great care to ensure the material is maintained in a state of control throughout the process.

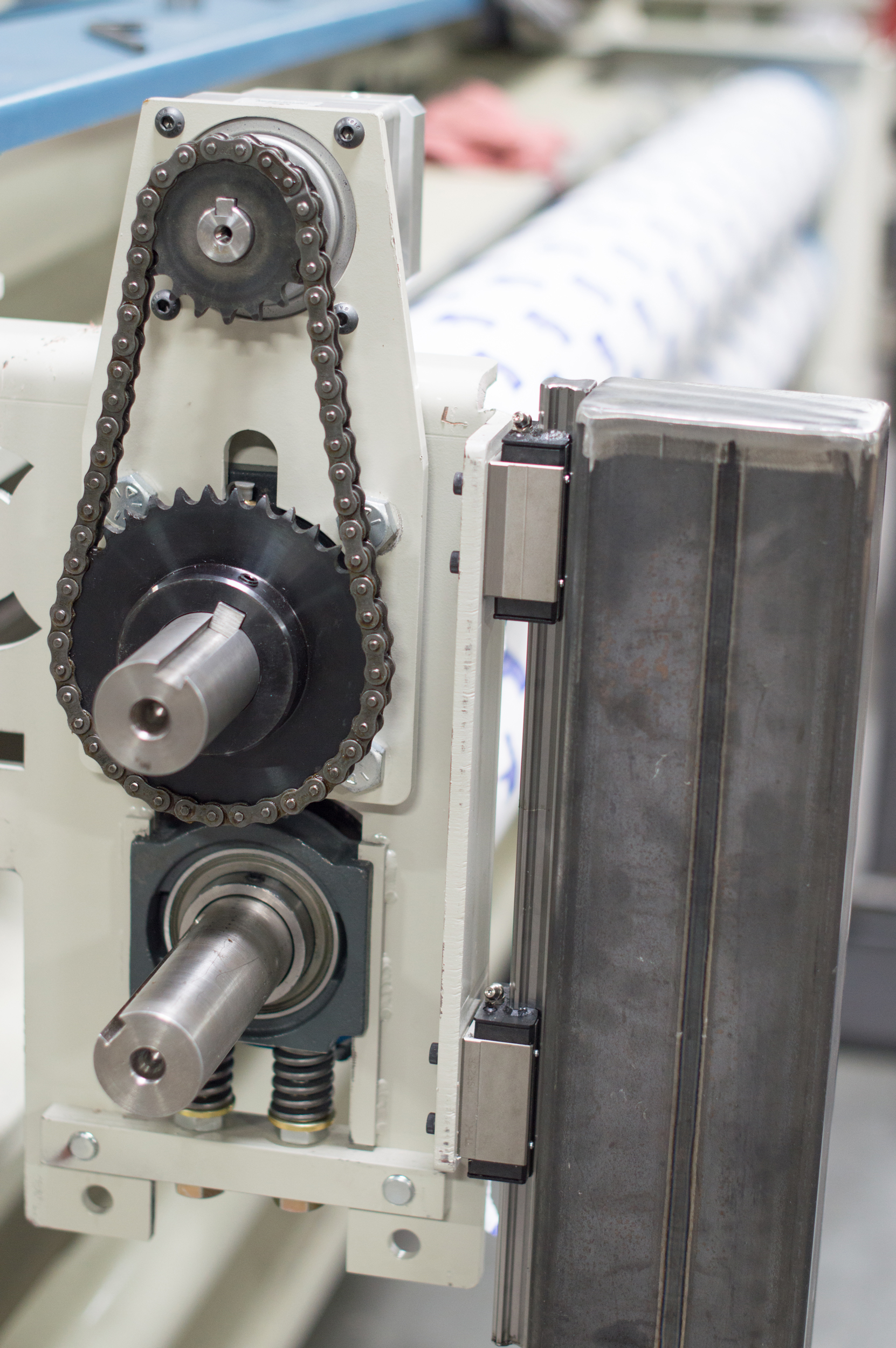

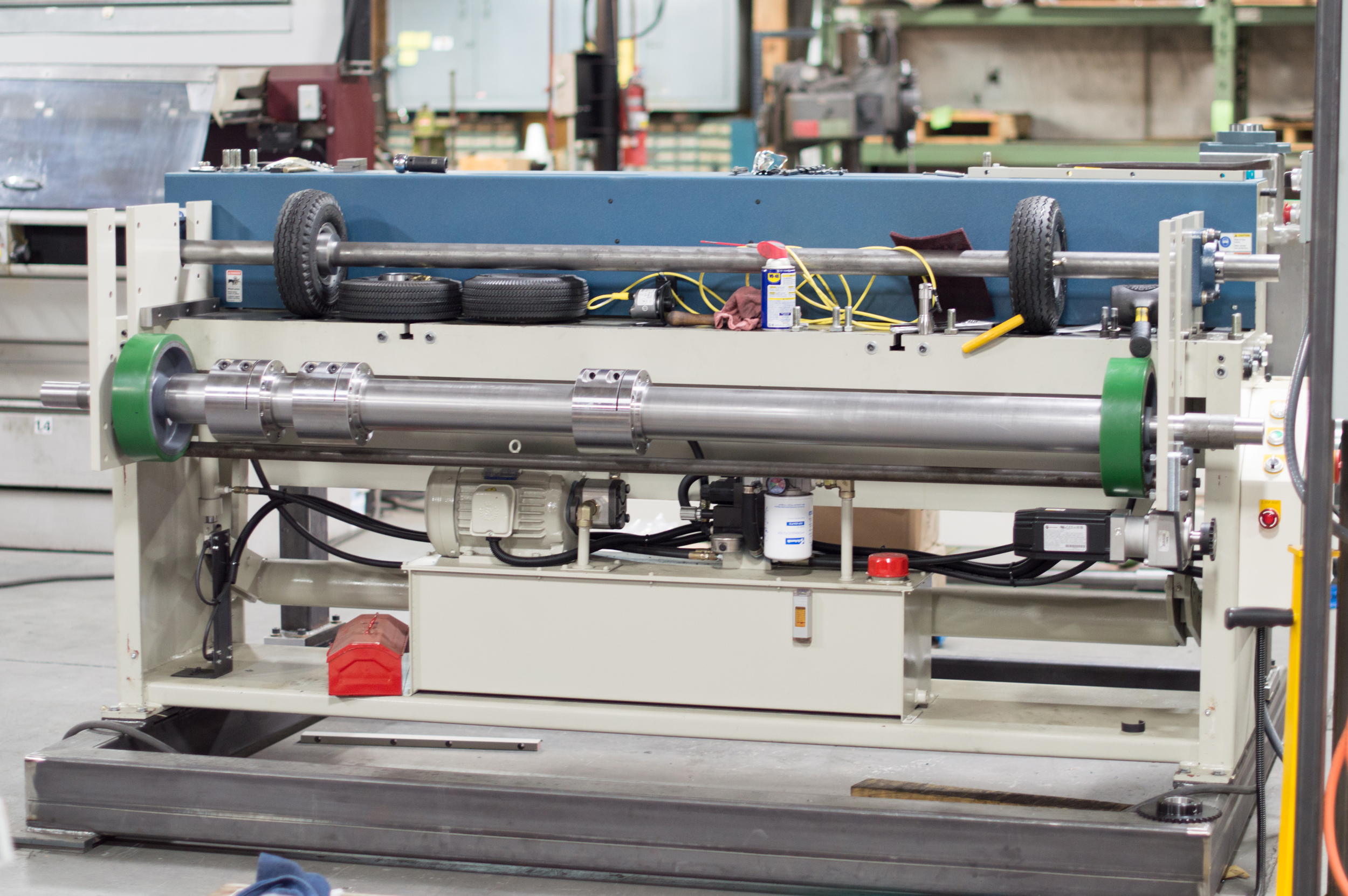

Robust design

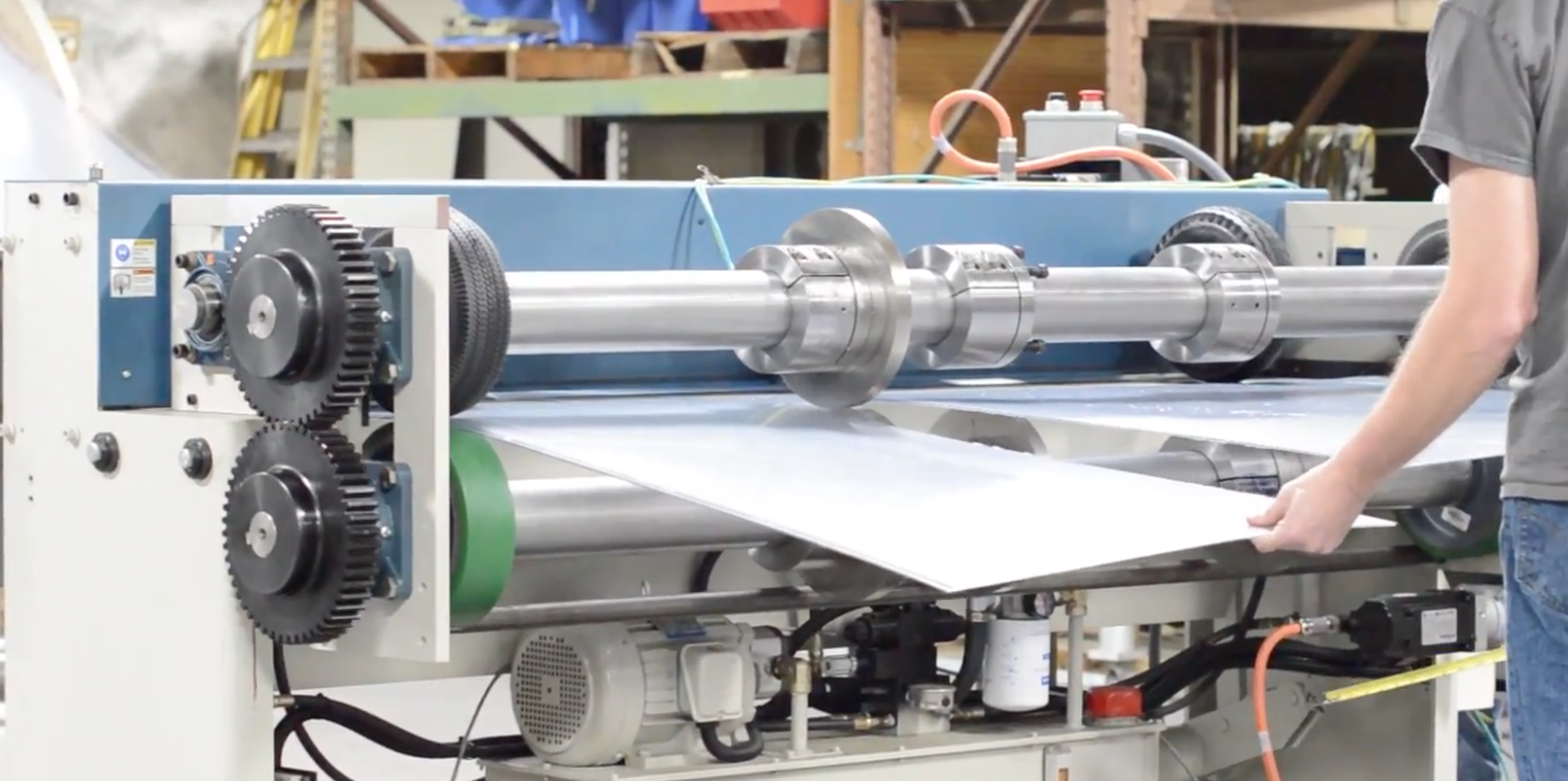

The Model 80P utilizes four 80” shafts that are 5” in diameter. Two shafts are utilized to displace the material and two shafts are utilized to drive the slitters. Each shaft is crafted with pride by skilled tradesman at Centerline Engineered Solutions.

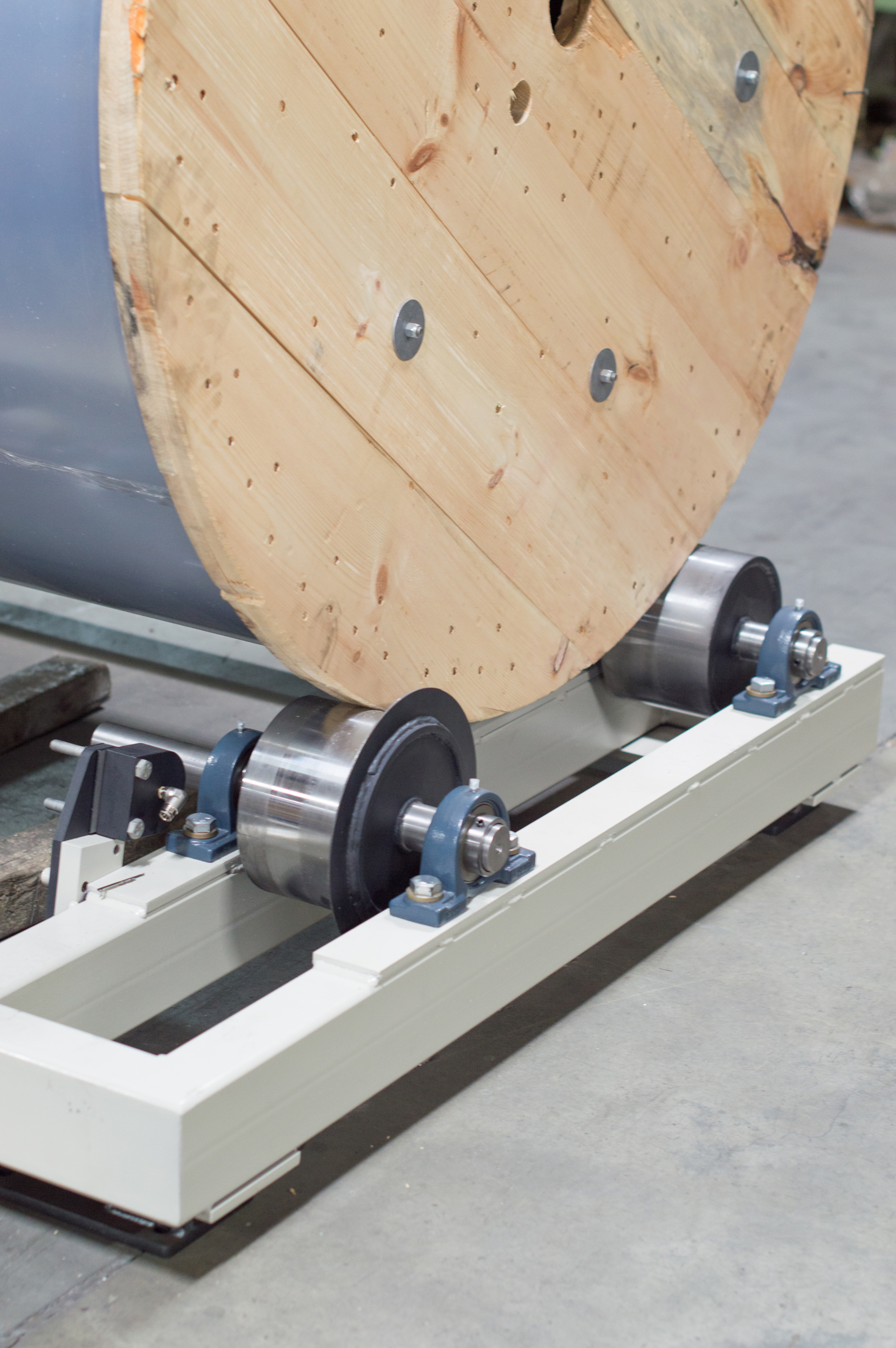

The Reel

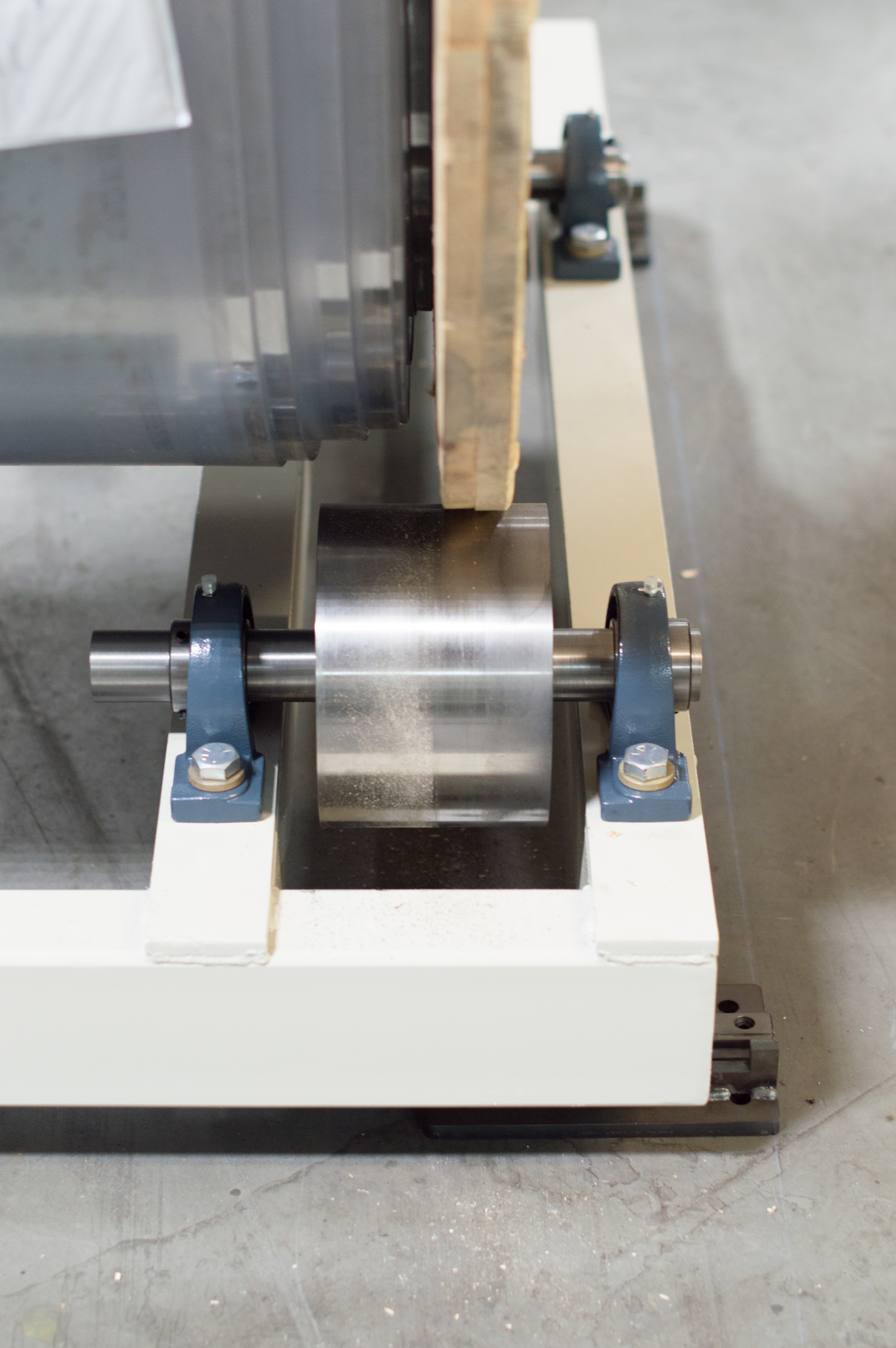

The reel of material is automatically rotated on four steel cylinders as the machine pulls the material from the reel and into the machine. The reel is held securely on a customized frame that includes the cylinders and a braking system. If the material can be securely transported on a reel, then it can be easily integrated with the Model 80P.

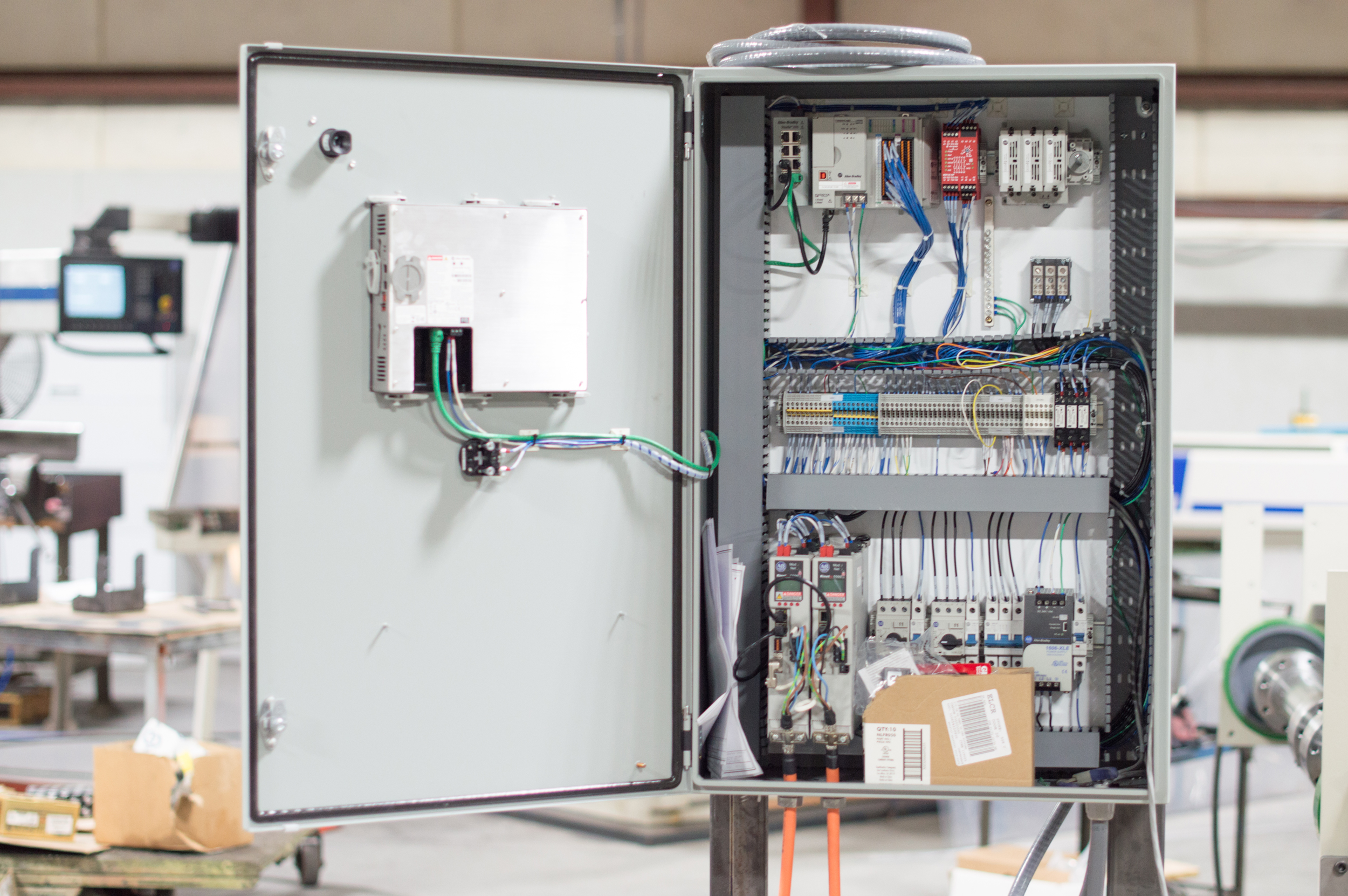

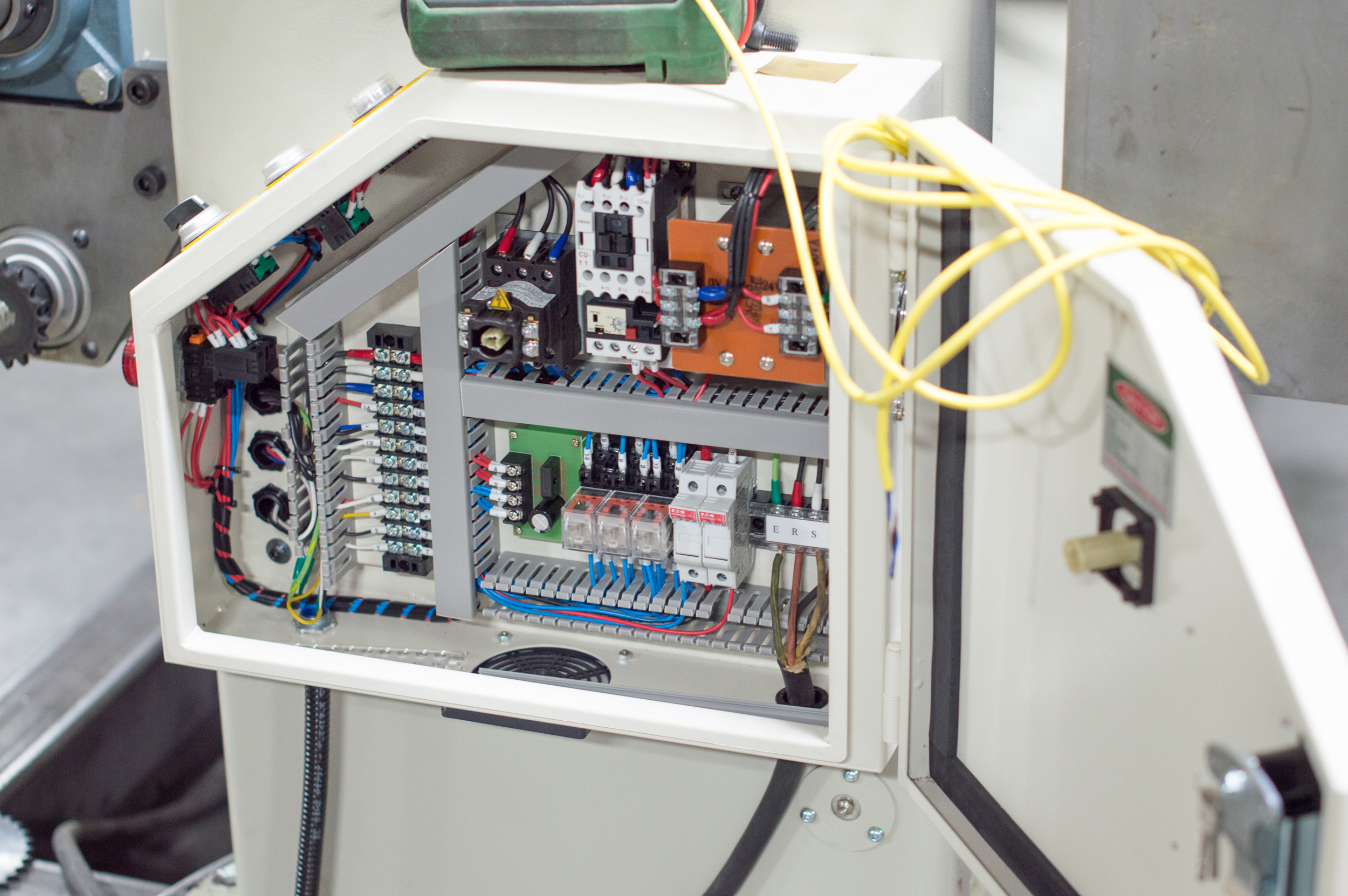

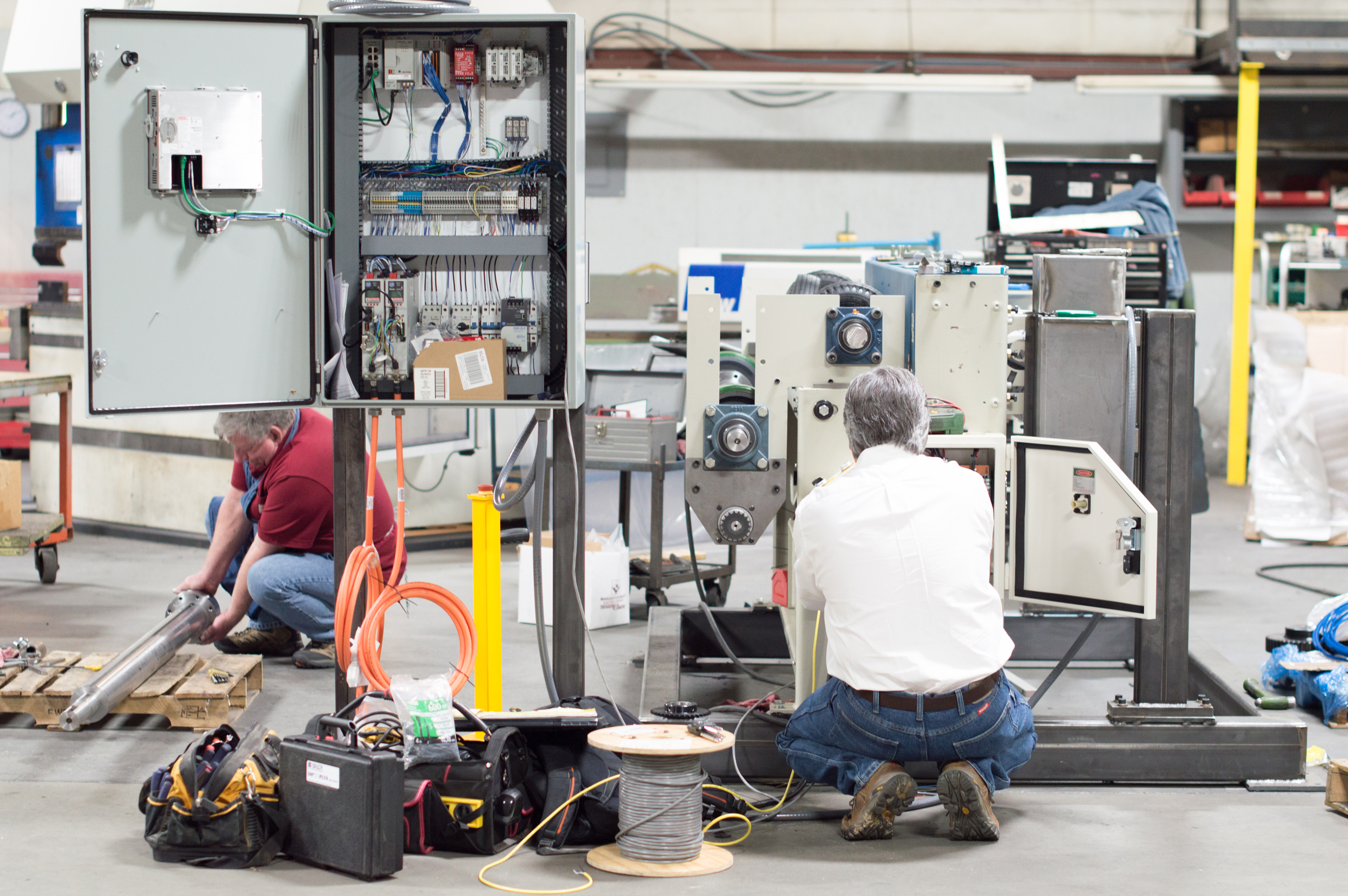

State of the Art Controls

The Model 80P utilizes a hydraulic pump to drive the guillotine shear and two servo motors to displace the material during the process.

The Model 80P is controlled with state of the art Allen-Bradley PLC and Allen-Bradley HMI interface. The HMI is configured to customer needs based on product and operating environment. The machine operates at 440 volts/3 phase. The Model 80P utilizes safety logic to ensure E-Stop circuits are linked. Keyence safety curtains come standard with this model to prevent employees from entering the operational area while the machine is functioning.