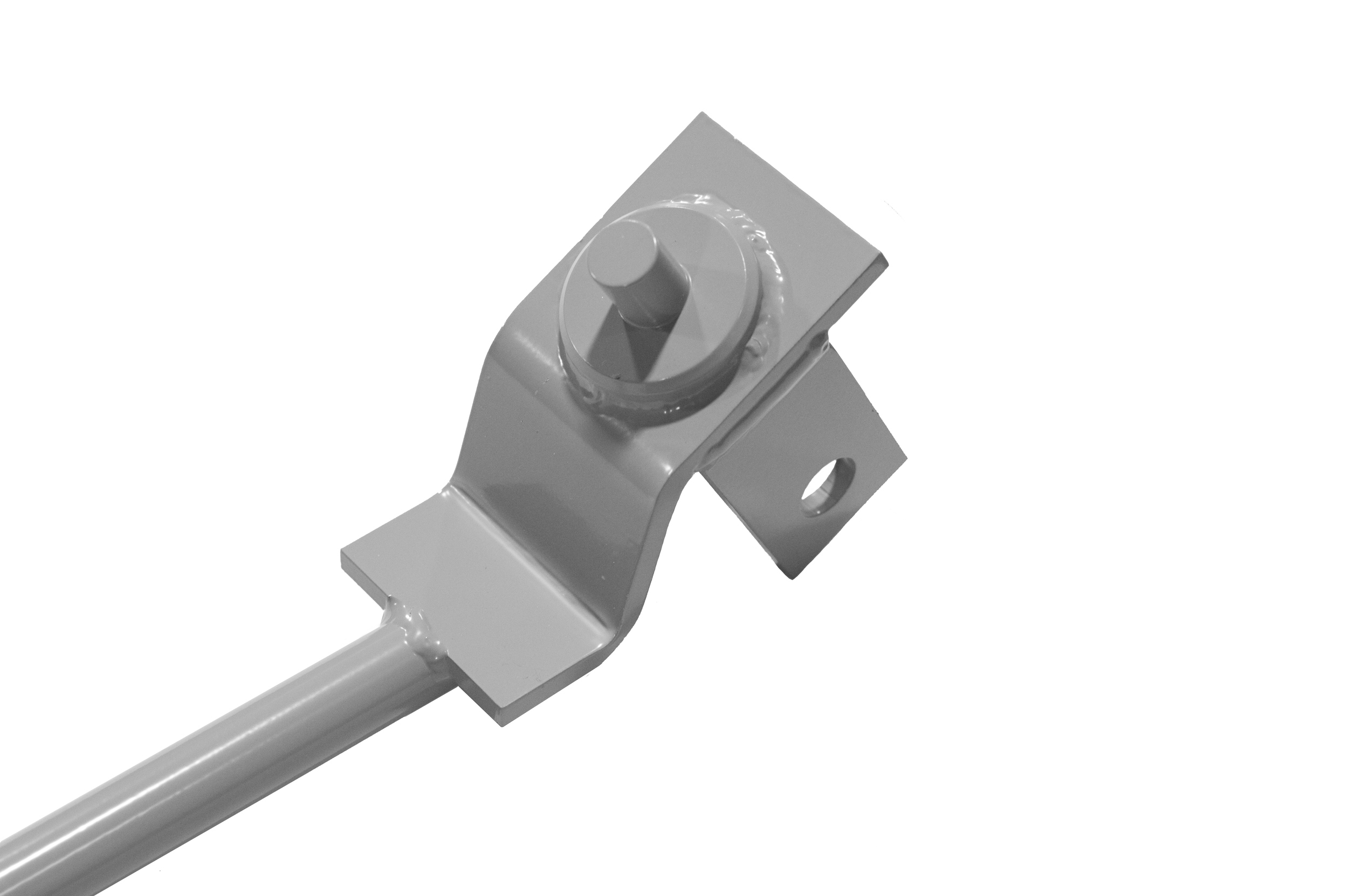

Centerline Engineered Solutions produces parts and assemblies in series of 1, 10’s, 1000’s, and 10,000’s. Our extensive capabilities include CNC lathes and CNC Milling Machines, Manual Machining, Laser Cutting, Bending, and multiple welding centers. We provide powder coating, heat treating, and plating solutions to fit our customer’s application. Providing an awesome customer experience is our objective. We accomplish this through relentless focus on quality that exceeds the requirements of our customer for all parts and assemblies. We maintain inventory for our partners to help ensure their success.

ISO 9001:2015

In 2022, Centerline Engineered Solutions received our ISO 9001:2015 certification. We strive to ensure our products and production process meet the industry standard. Our ISO certification ensures that our shop is leading in quality production, customer satisfaction and meeting industry requirements.

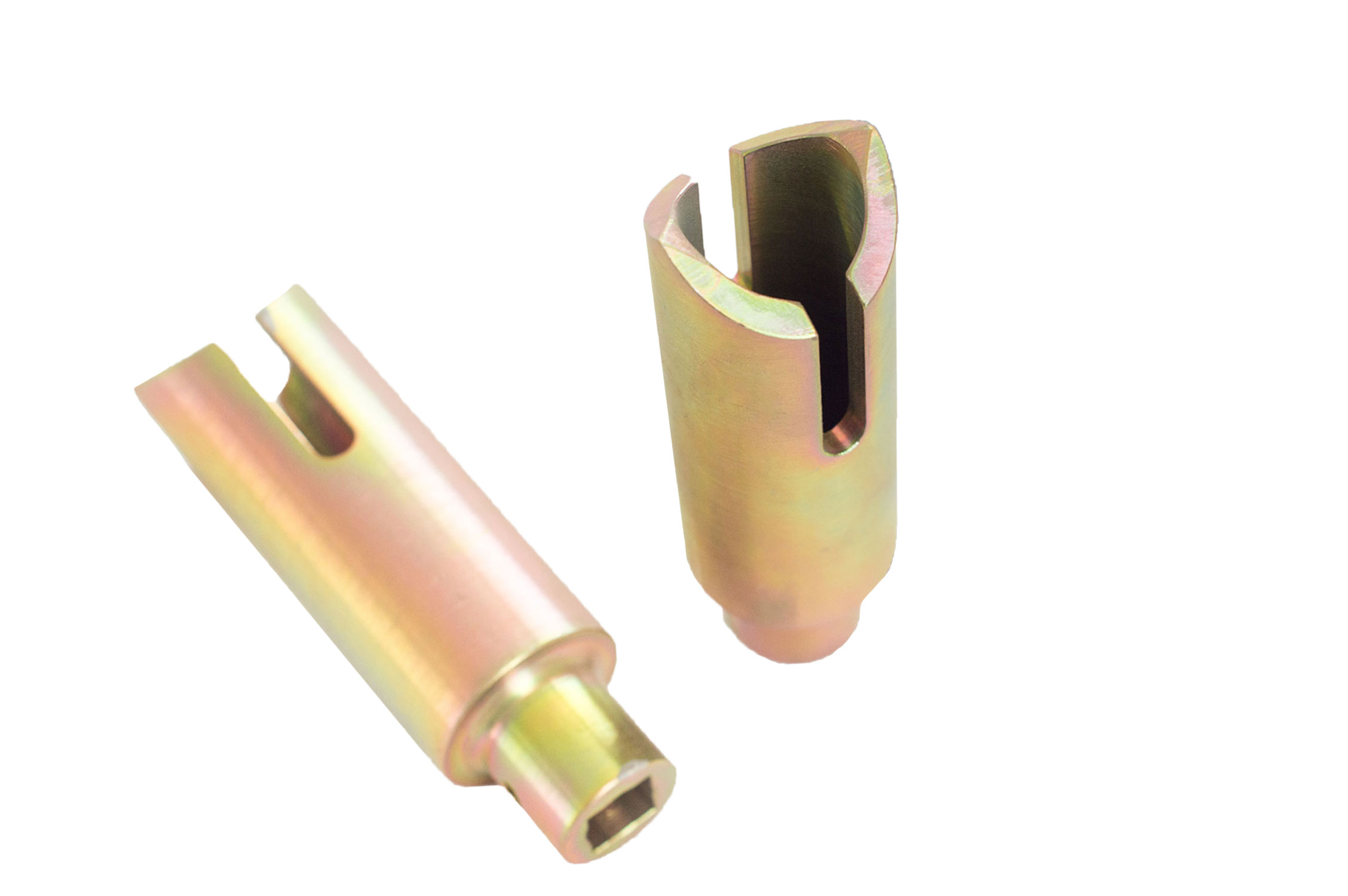

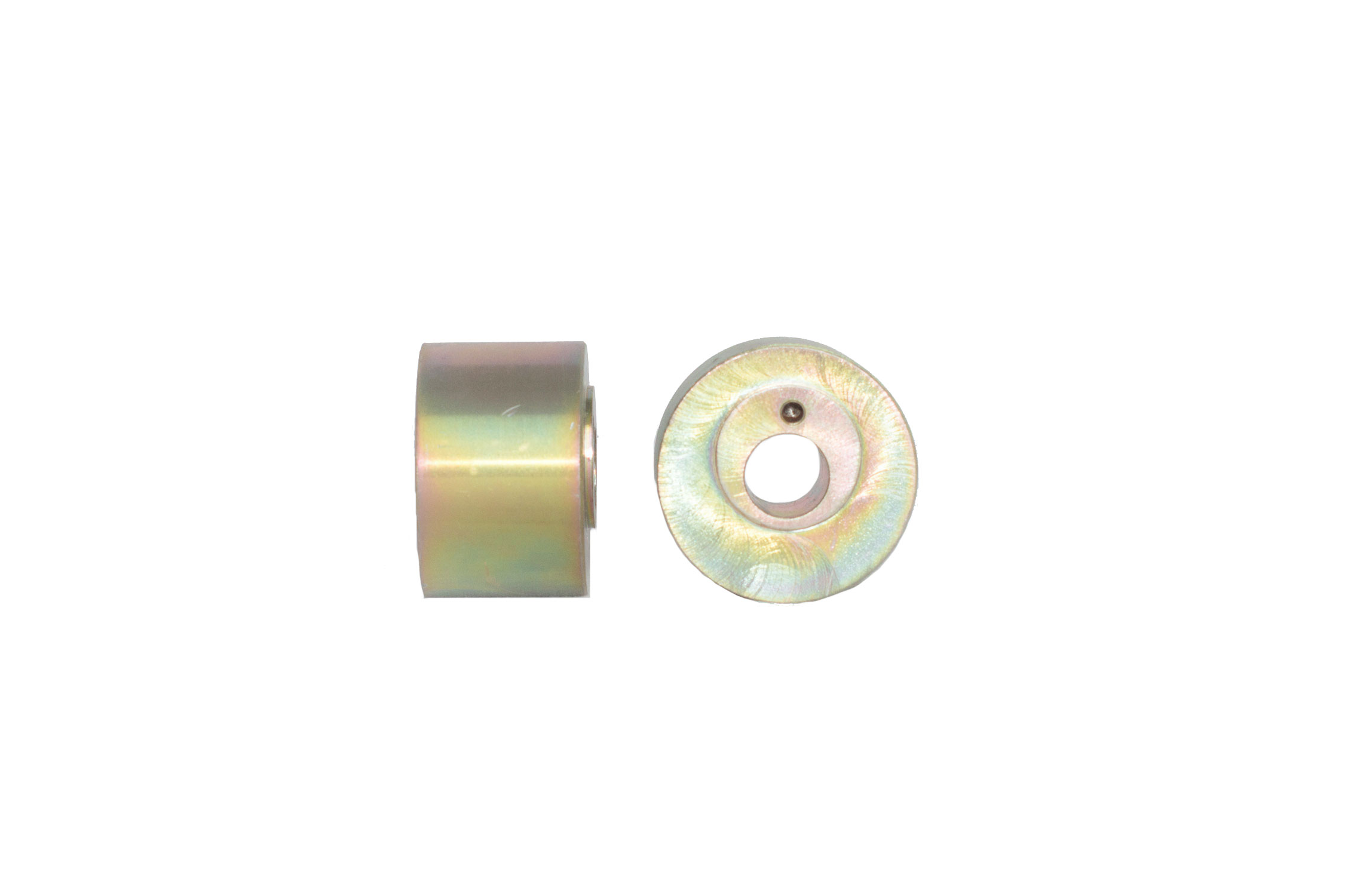

Machining Team - We can manufacture 12 feet long shafts to 0.005 inch spacers and almost anything in between. We can mill parts 4 feet in size to parts 0.02 inch in size. We can achieve tolerances to the +/-0.0001”. We can work from a print or we can reverse engineer the part and provide you with a print. We produce parts from ferrous and non-ferrous materials.

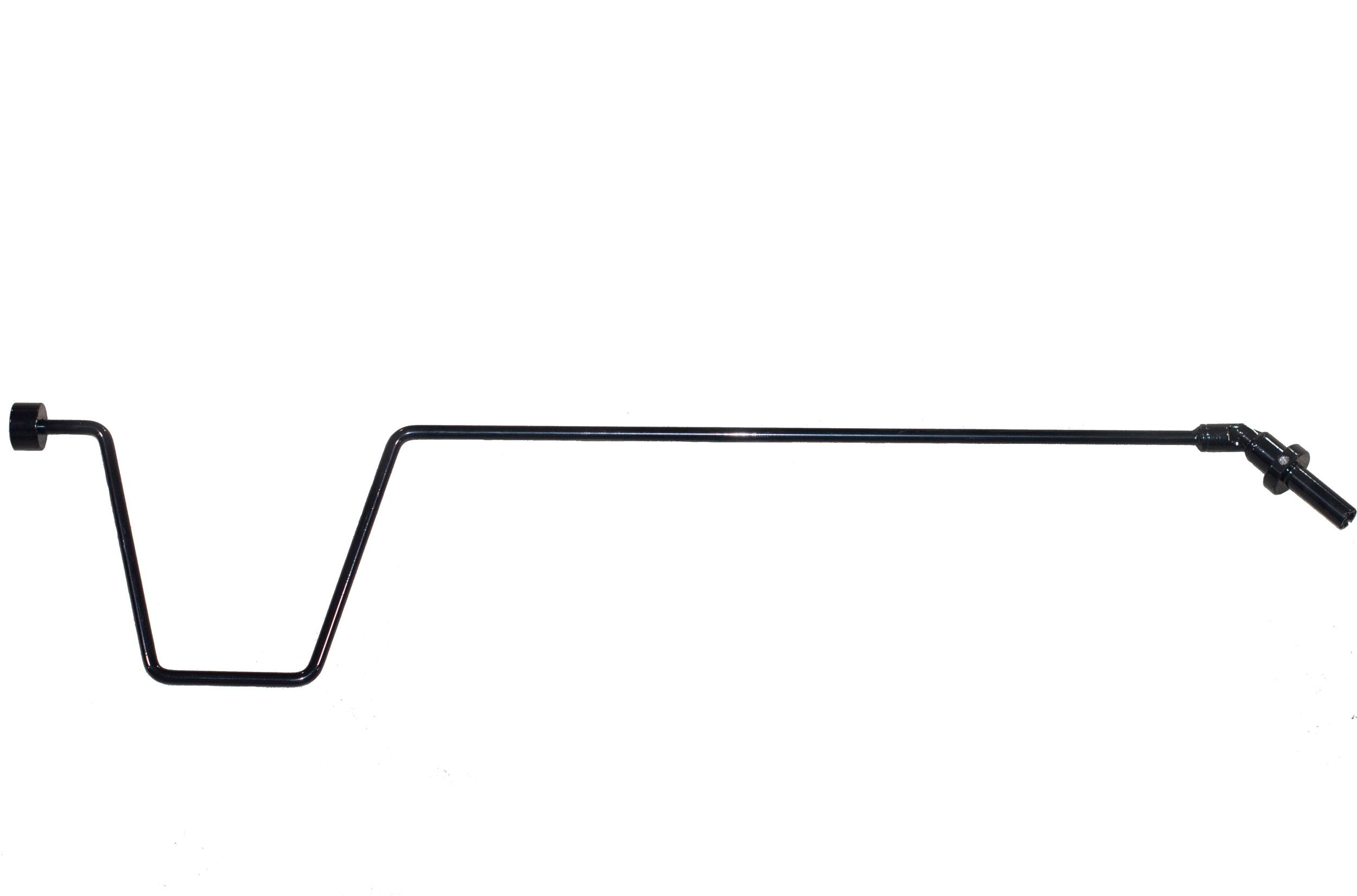

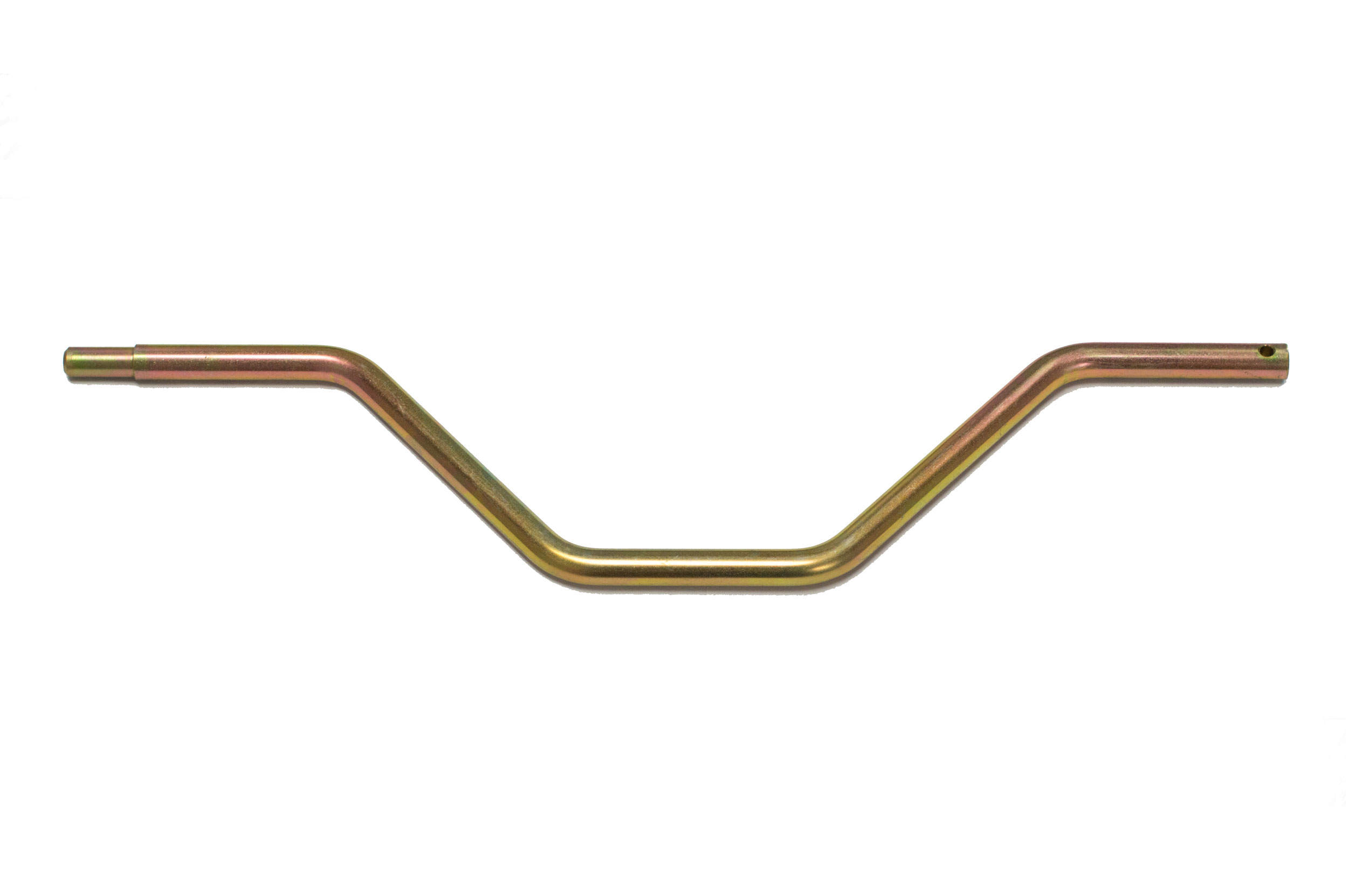

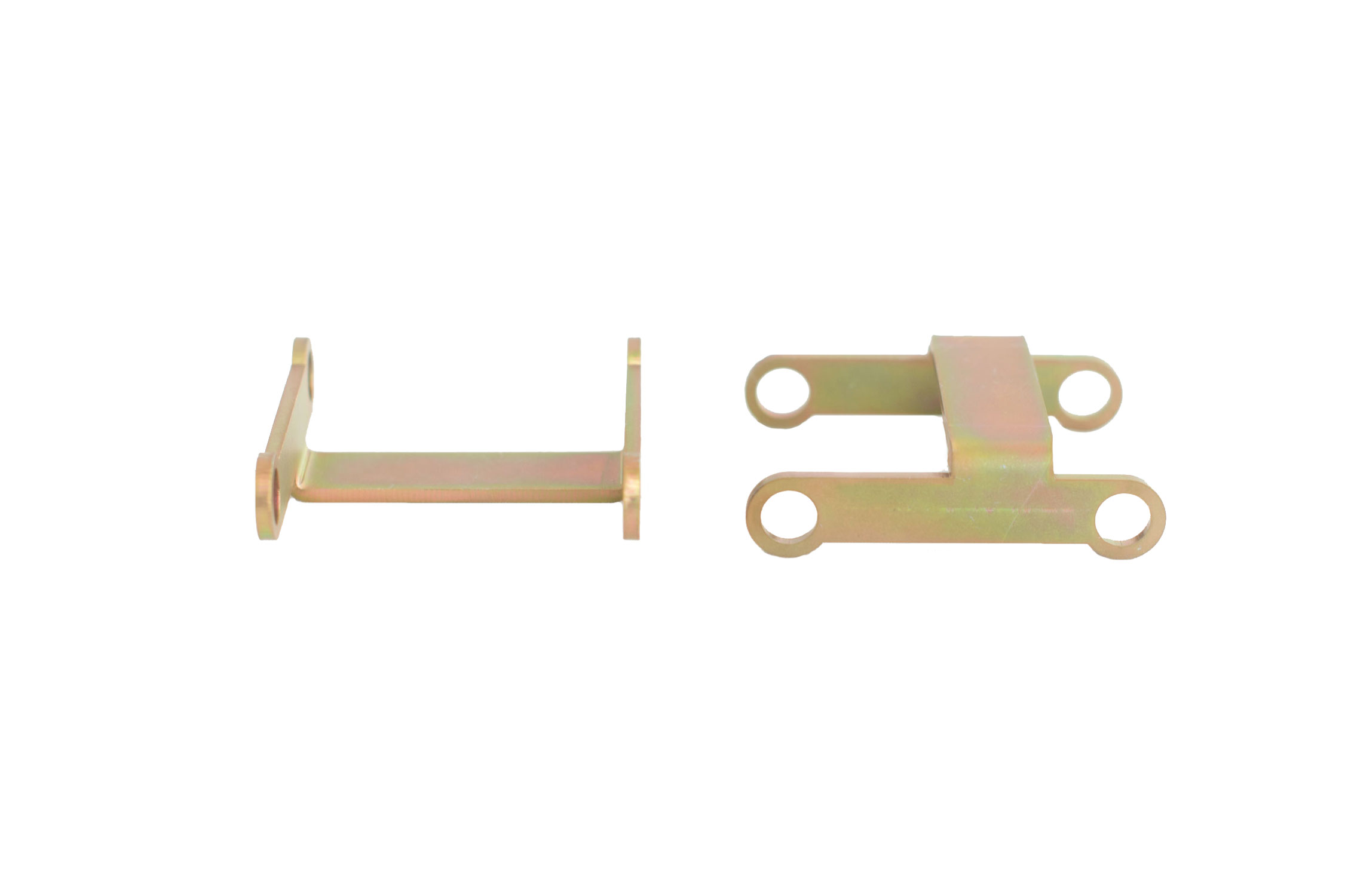

Fabrication Team – We can cut and bend metal from 22 gauge to 2.0 inch. We go to great lengths to ensure all angles are to your specification whether a simple 90 degree bend or a triple bend is required with numerous knockouts included. We assemble and install hardware such as pem nuts and weld nuts.

Welding Team – We have the capability to tig weld, mig weld, spot weld, braze weld, stud weld, and stick weld. Our welders have over 80 years of welding experience. We can provide certifications as required. We weld ferrous and non-ferrous materials. We also offer pharmaceutical and food grade welding options.

Expanding Capacity

Over the last 6 months of 2017 we have invested heavily in our machining / fabrication / welding areas, and increased capacity by 40%. This was achieved through additional equipment and additional technicians. It has been an exciting time and we appreciate our customer's trust in the Centerline Engineered Solutions team.

Quality Enhancements

Our focus in 2017 was to upgrade our quality system. Several process and equipment changes were implemented to ensure product quality continues to improve so that we can continue on our quest to delight our customers.